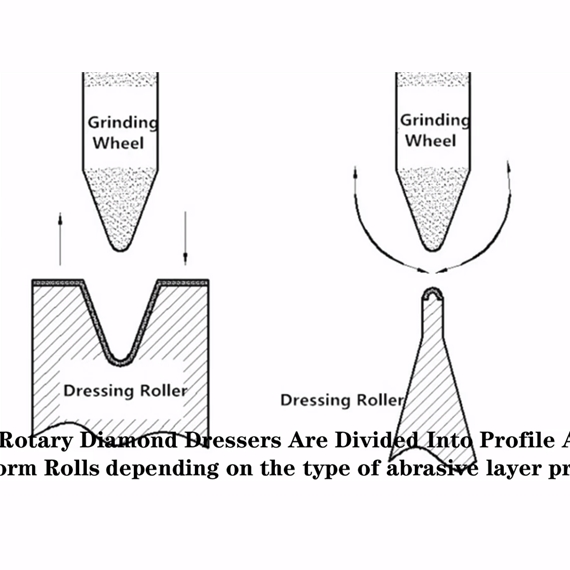

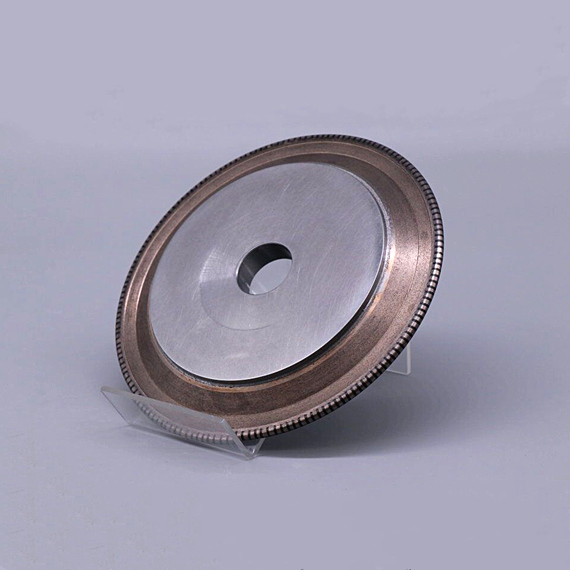

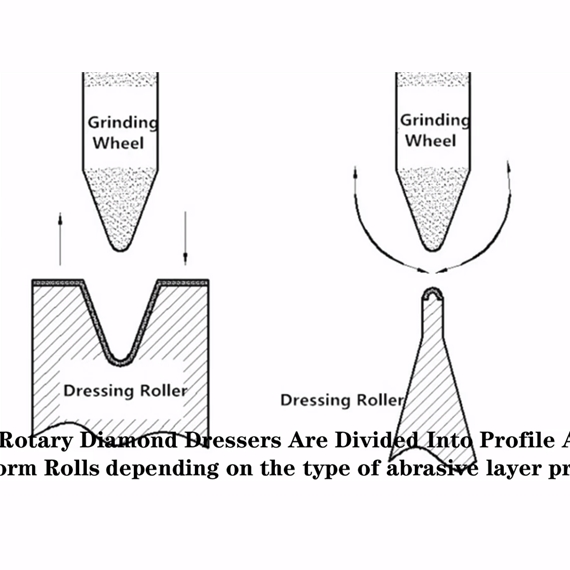

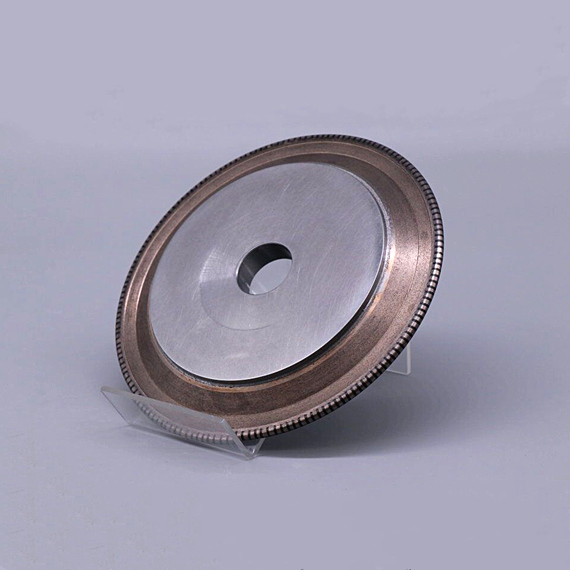

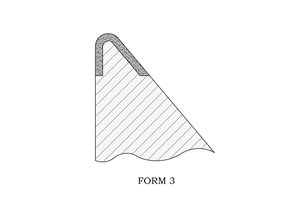

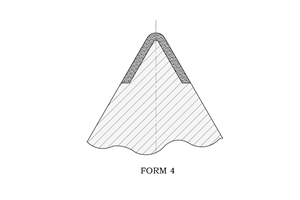

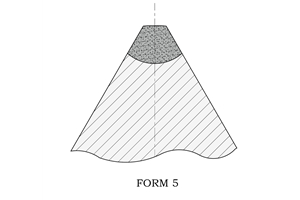

Profile rotary dresser roller

The CNC dressing technique can be used in all fields of grinding production, especially for small and medium production lot sizes and for prototype applications. The profile of the grinding wheel is created by the CNC controlled process that moves the rotating form roll along the target contour. Form rolls are therefore not restricted to a specific workpiece but can be used flexibly.

More diamond dressing rolls are used successfully in the following applications:

• the manufacture of ball and roller bearings,for grinding raceway profiles.

• drive technology for manufacturing linear guides, ball screws, gear teeth or racks.

• turbine industry for grinding the blades as well as the blade root and fir tree profiles.

• the automotive and -supply industry for grinding camshafts, crankshafts and gear shafts, fuel injection compo�nents, piston rings, joints, ball screw drives etc.

• grinding of precision tools such as taps, twist drills, milling cutters, reamers etc.

• general mechanical engineering for grinding hydraulic or pump components.

The advantages of profile roller dressers are

• Reduction of dressing costs per workpiece

• Optimized utilization of machine capacity

• Automation of the dressing process

• Repeatable high precision with low workpiece rejects

• Rapid incorporation of complex profiles in the grinding wheel